- Home

- Products

- Services

- Projects

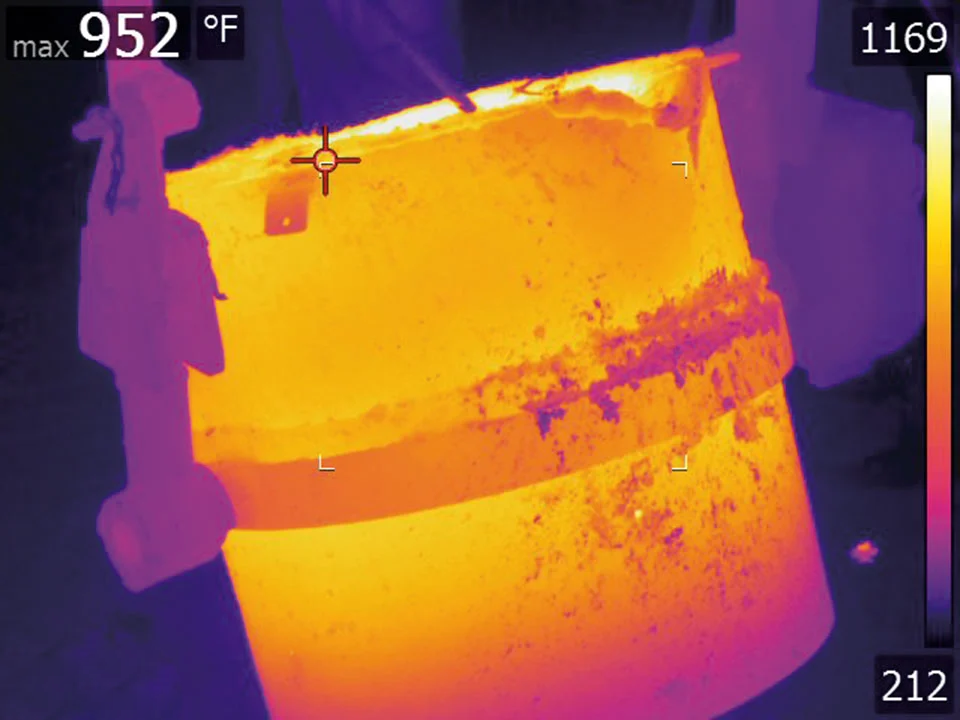

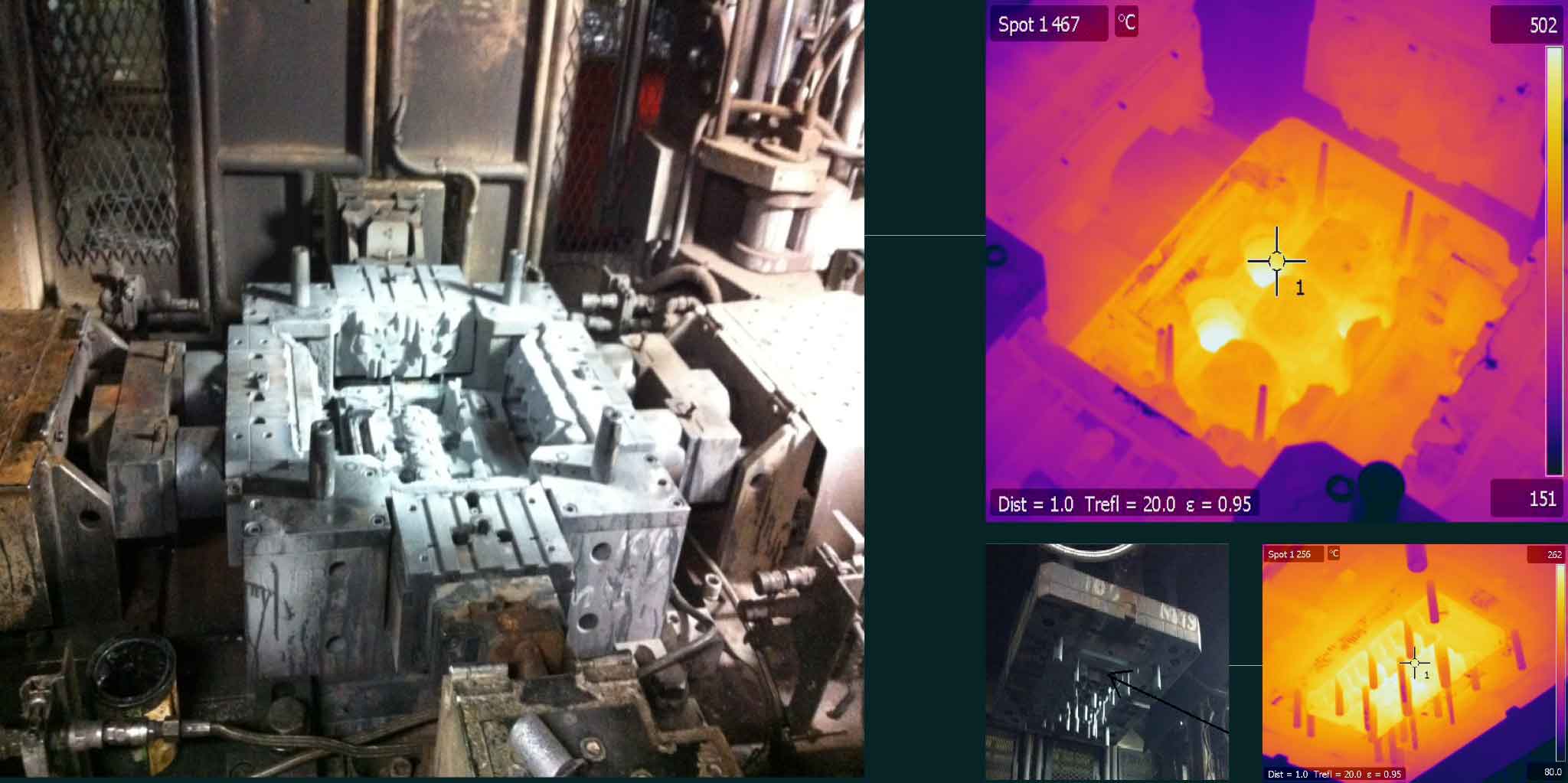

Die Casting Thermal Automation

Die Casting Thermal Automation Phase Parallel Tester

Phase Parallel Tester AHU AC Controller

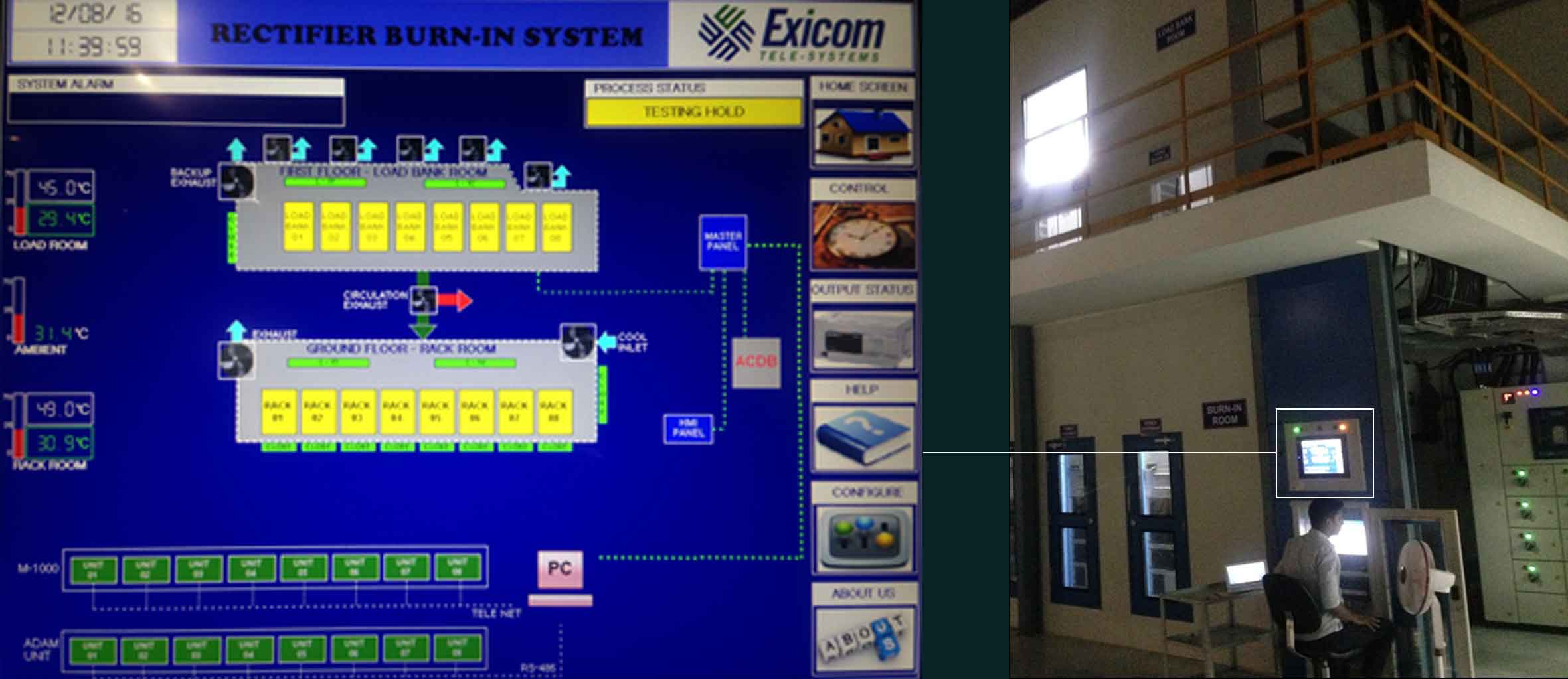

AHU AC Controller Burn-In-Room / Testing Lab

Burn-In-Room / Testing Lab Heat Controller for Missile testing

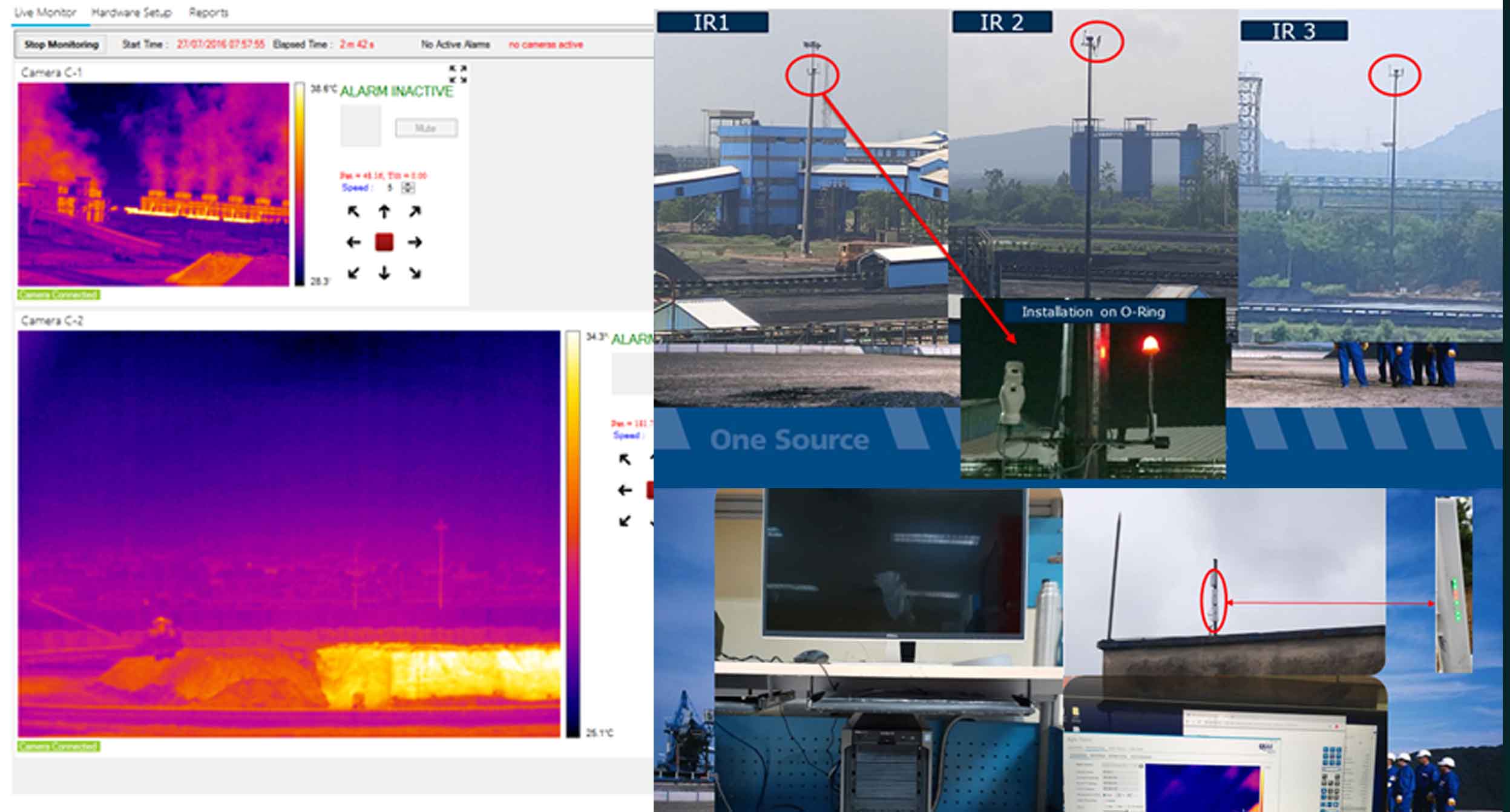

Heat Controller for Missile testing Coal Pile Thermal Monitoring

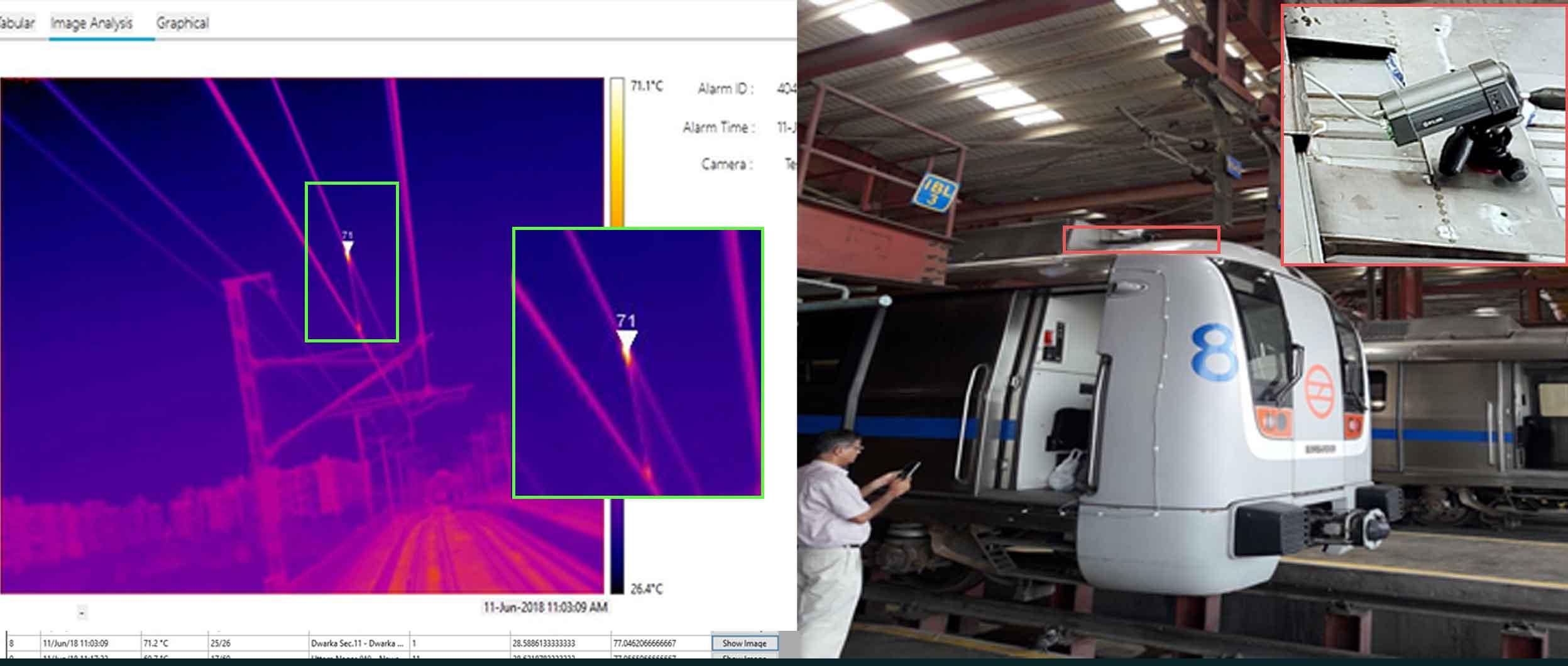

Coal Pile Thermal Monitoring OHE Hotspot Scanning System

OHE Hotspot Scanning System IO card Integration with IR Scanner

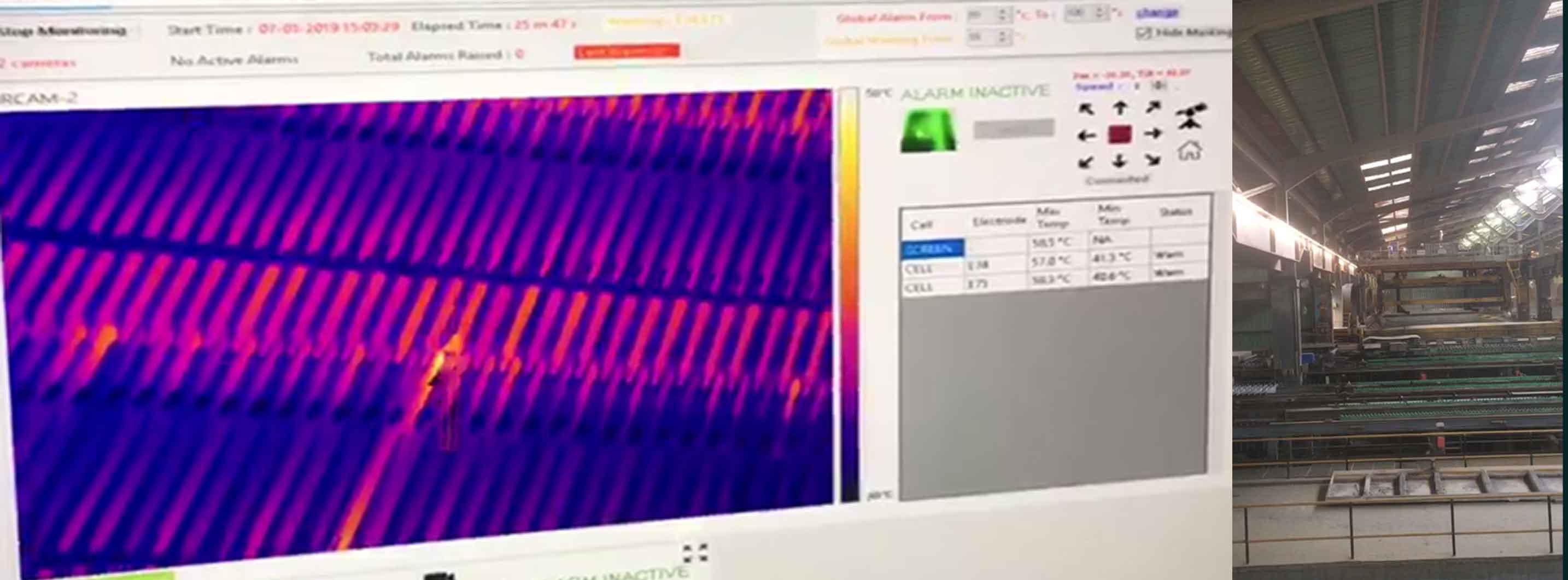

IO card Integration with IR Scanner Cell Electrode Hotspot Detection

Cell Electrode Hotspot Detection Dough Temperature Monitoring

Dough Temperature Monitoring Thermal Automation Panel

Thermal Automation Panel Thermal Scanning

Thermal Scanning

- SIDEVEX Catalogue

- SIDEVEX Group

- Contact

- About Us

CALL US DIRECTLY

+91 9650835074

+91 8958003315

Corporate Office

1st Floor, Siddhi Vinayak Complex, Basai Rd, opposite Desi Mall, Basai Enclave, Gurugram, Haryana 122006

Workshop Address

Shop No. 1&2, Plot No.138, Rajiv Colony, Gurgaon, Haryana - 122001

Collaboration, work enquires or just say Hello.नमस्तेਸਤਿ ਸ਼੍ਰੀ ਅਕਾਲ

Contact Info

+91 9650835074

+91 8958003315

[email protected]

Corporate Office

1st Floor, Siddhi Vinayak Complex, Basai Rd,

opposite Desi Mall, Basai Enclave,

Gurugram, Haryana 122006

Workshop Address

Shop No. 1&2, Plot No.138,

Rajiv Colony,

Gurgaon, Haryana - 122001

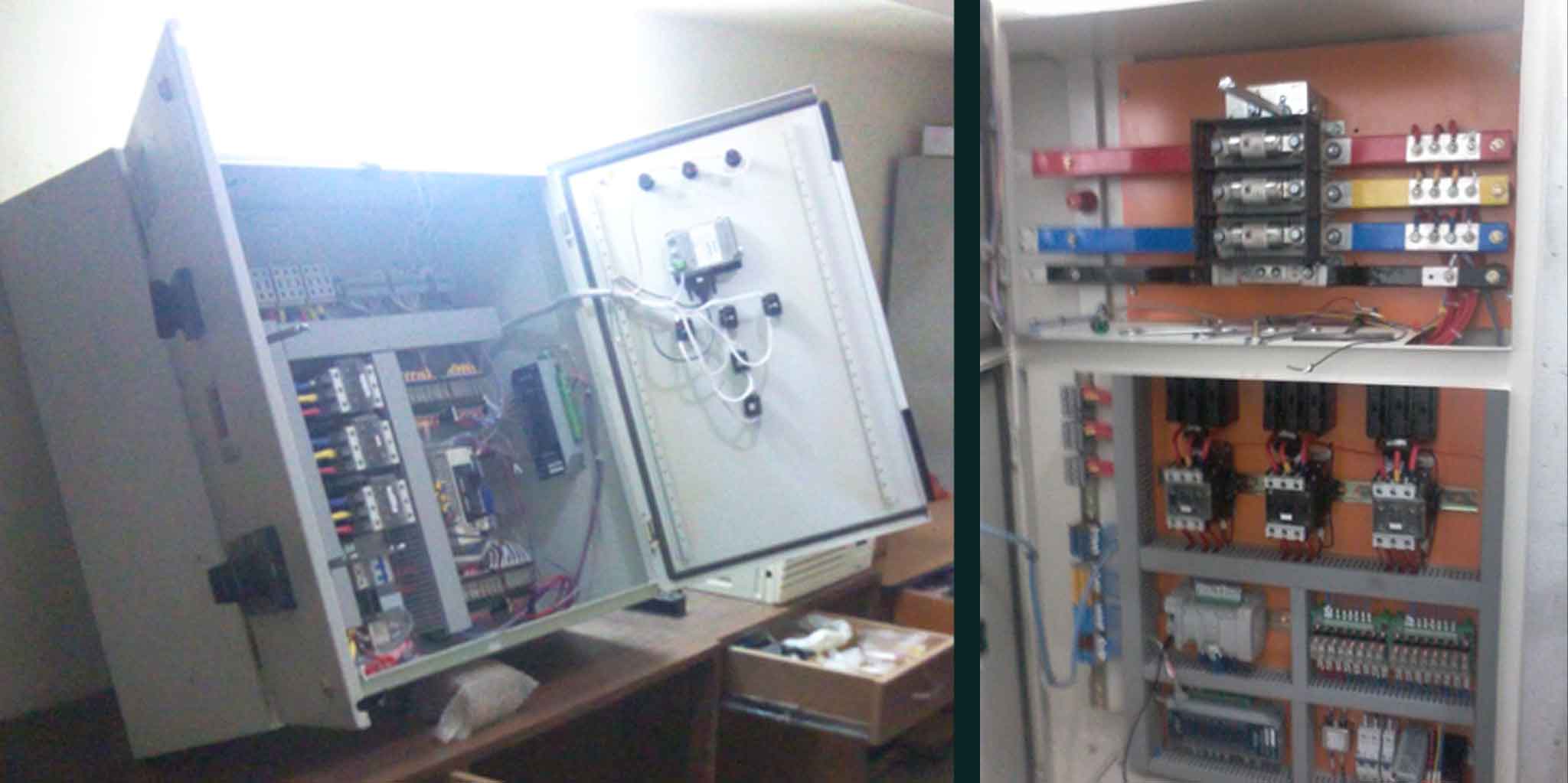

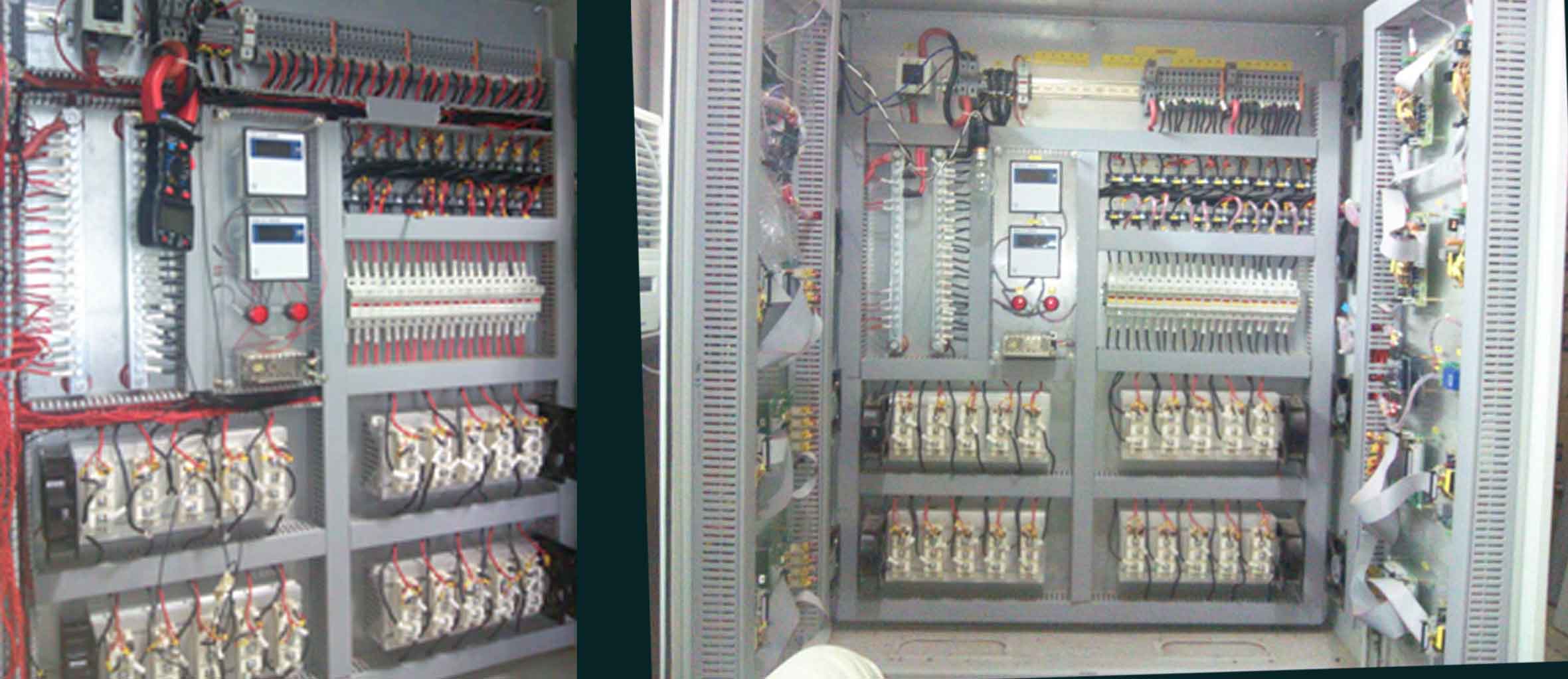

PROJECT / SOLUTION

Die Casting Thermal Automation

KEY FEATURES

PROJECT / SOLUTION

Die Casting Thermal Automation

KEY FEATURES